DURABLE

To this day, our commitment to excelent cratsmanship has not changed.We continue to make high-quality boots with the best materials we can find to create durable products.

To this day, our commitment to excellent craftsmanship has notchanged. We continue to make high-quality boots with the bestmaterials we can find to create durable products.

ABOUT THE COMPANY

The origin of inheritance

In 1978, ROCKLANDER boots began production at a small factory on River Street in downtownROCKLANDER Fals, Wisconsin. Today, ROCKLANDER boots continue to live up to this tradition.providing high-quality sturdy boots and shoes for all purposes. ROCKLANDER is more than just apair of boots, it is built to honor the courage and determination of the lumberjacks and engineerswho pave, build roads and build buildings for us. Built with uncompromising quality and standardseach pair of ROCKLANDER boots are the most well-made, reliable and authentic boots that havebeen passed down for more than a century of long tradition of innovation, comfort and durability.

Featured Projects

Our Showcase

finance

Financial Planning

consult

Information Technology Consulting

Business

Business Monitoring

finance

Information Technology Consulting

finance

Digital Strategy

finance

Free Consultation

FAQ

Technical Features

Our product design revolves around three key concepts: protection, comfort and design. Each of our solutions is challenged by R&D experts. This allows us to provide more advanced and unique solutions

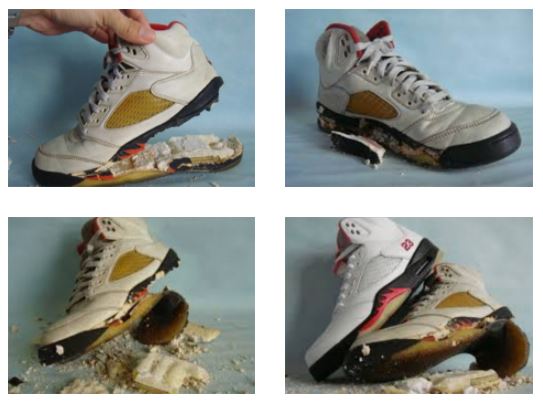

Explanation of the reasons for hydrolysis and sole fragmentation

Many of our shoes have the soles attached to the uppers by a process where 2 materials are brought together in a mould, the resultant chemical reaction forms polyurethane (PU). the use of polyurethane makes a lightweight flexible sole which is not only shock absorbent but also extremely hard wearing, that’s why polyurethane is ideal for shoes.

One of the main technical challenges with polyurethane is overcoming an ageing deterioration known as “hydrolysis Hydrolysis is the chemical breakdown of the PU polymer and the resulting physical breakdown or crumbling of the PU sole by the attack of water (usually in vapour form), occurring over a period of several years (even when the shoes are in store!).

This process is accelerated by warmth and high humidity. lt will,therefore, happen more quickly in tropical climates, but also in confined spaces (such as lockers) if the safety shoes are put away damp, In the most advanced state of hydrolysis, the Pu sole will lose all its physical strength, thus cracking or crumbling.

The ROCKLANDER PU sole has been improved to

increase the resistance against hydrolysis and performs better than any average safety shoe. Below you will read why!

The ROCKLANDER PU sole

There are 2 types of Pu soles. There is a Polyether based PU sole and a Polyester based PU sole. Polyether based PU soles have a high resistance against hydrolysis and low oil resistance. Polyester based PU soles have a low resistance against hydrolysis and high oil

resistance.

Safety shoes are always using a polyester based PU sole. The basic PU sole used in most safety shoes on the market lasts for 1.5 year in

tropical conditions and 3 years in normal conditions.

The Safety Jogger PU sole, upgraded with improved resistance against hydrolysis, lasts for 4 years in tropical conditions and 8 years in normal conditions. Making our safety shoes a reliable product of

endurance.

Do you have any questions about hydrolysis or crumbling shoe soles?

Don’t hesitate to contact us right away, We’re social!

Individual orthopedic solutions for safety shoes

Did you know that almost two-thirds of all adults need an individual orthopedic solution? However, when it comes to safety shoes, you are not allowed to use your standard orthopedic footbed. lf safety shoes are delivered with removable footbeds, you can only replace those footbeds with identical ones or with footbeds that are certified for this particular product.

That is why Safety Jogger has partnered up with the Dutch

company NESKRlD, which specializes in creating orthopedic footbeds that meet both individual needs and the official safety

footwear regulations

But how does that work exactly? We’ll explain it in the video below:

In summary:

Do you have special needs for your feet? With the help of Neskrid, you can replace the original Safety Jogger footbed with a footbed that is custom-made for you and still has the same safety certifications. For example: if your previous footbed was featured with ESD, your new NESKRlD footbed will have the same properties

Puncture resistant boots, steel vs.fabric midsoles

Safety footwear and its protective grade is best chosen after evaluation (risk assessment) of the potential dangers in the work environment. The footwear should always be used as a last resort,is the final line of defense against hazards, after all other reasonable or practical measures have been taken to manage the risks of the workplace. Impact, compression and puncture are the most common! types of foot injury.

Common dangers are related to the kind of materials that are handle by the worker, risks of objects falling on or rolling over the feet or sharp objects that could penetrate the outsole of the shoes

Below we are going a little deeper into puncture resistant boots and the differences between steel midsoles and woven fabric midsoles in puncture resistant boots.

Do you need advice or do you still have a question about puncture resistant boots? Don’t hesitate to contact us right away, We’re social!

Puncture resistant boots

Steel vs. woven fabric midsoles

Puncture flesh wounds are particularly awful because screws, spikes, sharp scrap metal or the famous rusty nail puncturing the foot, can deposit bacteria and debris deep into the body, leading to dangerous infections and/or permanent foot damage.

The protective midsoles are embedded during the manufacturing process, between the insole and outsole of the puncture resistant boots. The standard specifies that the protective midsole of puncture resistant boots cannot be removed without damaging or destroying the boot. 2 main materials are used for protective midsoles: steel and Aramid (woven fabrics with high tenacity; eg. Kevlar by Dupont, Twaron by Akzo)

When puncture resistant boots have a woven fabrics midsole, they are most likely to have a composite toe cap too to create a metal-free, lightweight work boot. A crucial element on sites where metal detectors are used as employees enter and leave, for example high-security environments, such as airports, governmental buildings and military bases, where the scanning aims to prevent weapons from making their way in.

We made a list with all the differences you should know about a steel or woven fabric midsole in your search for the puncture resistant boot that suits your work

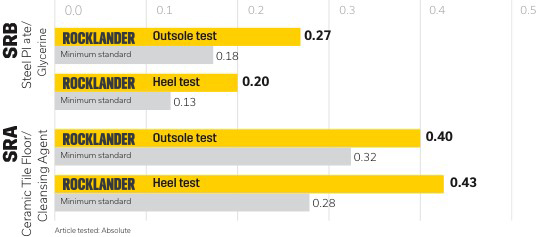

Slip resistance: what is the difference between SRA, SRB and SRC?

Did you know that slipping, tripping and falling are the main causes of accidents on the work floor? That is why ROCKLANDER offers a wide selection of shoes with an outsole that exceeds the general European slip resistance standards by far.

However, it’s important to know that some shoes on the market claim to be ‘slip resistant’ without them being formally tested in a laboratory. You can only be 100% sure your safety footwear is slip resistant when your shoes have a slip-resistant rating like SRA, SRB or SRC. But what is the difference between these three ratings? Watch the explanation in the video below:

In summary:

ROCKLANDER SRC slip-resistant soles pass both the SRA and the SRB test with glance. They not only fulfill the minimum standards but exceed them remarkably! You will notice that almost every Safety Jogger shoe is provided with an SRC-certified slip-resistant sole.

What's in it for you?

The common goal of our product managers and services is to offerreliable, sustainable, high-performance products in compliance with theregulations and/or standards of each territory where they are used.

- Unique quality/price ratio

- Always-in-stock guarantee

- Advanced technology & innovation

- Only specialized distributor channels

- Technical support & live chat

- Well-balanced collection

- Contemporary & timeless design

- Global marketing support

- Available worldwide

Eco-design

Our offer includes systematic eco-design in each of our specifications, in order lo drive our development while limiting our impact on future generations

Email Address

david@vaultex.cn

Phone Number

(+86)136-7682-0199